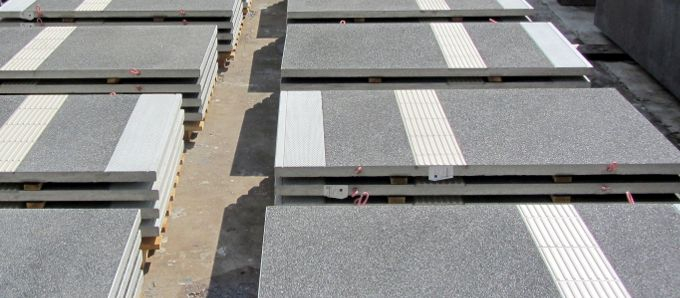

The modula®flex system developed by Hering provides a solution for this that can be implemented with great cost effectiveness. If the old platform is still able to support a load, no dismantling is necessary. Very slim, thin elements measuring a mere 8 centimetres and made of textile-reinforced concrete are used for the new platform slab system. These offer the advantage that, due to the textile glass-fibre reinforcements, they do not corrode and therefore the concrete cover (at least 5.5 centimetres for reinforced concrete) stipulated in DIN EN1992 can be dispensed with. Moreover, the system does not need to be grounded.

With the slim design up to 60% weight and resources are saved as compared to the conventionally-used reinforced concrete design, which is a great argument for the innovation also with regard to sustainability. The complete slab system is prefabricated in the Hering Bau factory including the desired surface design and is delivered and installed “just-in-time”. After the successful realisation of several pilot projects at the end of July 2017 DB Station&Service AG awarded user approval for the modula® flex system. The result is an innovative system for fast, cost effective reconstruction and raising of existing platforms which is now available.

For more information please visit: bahnsteige@hering-bau.de