Roofing systems for Deutsche Bahn AGBodenheim

Roofing systems for Deutsche Bahn AGBodenheim

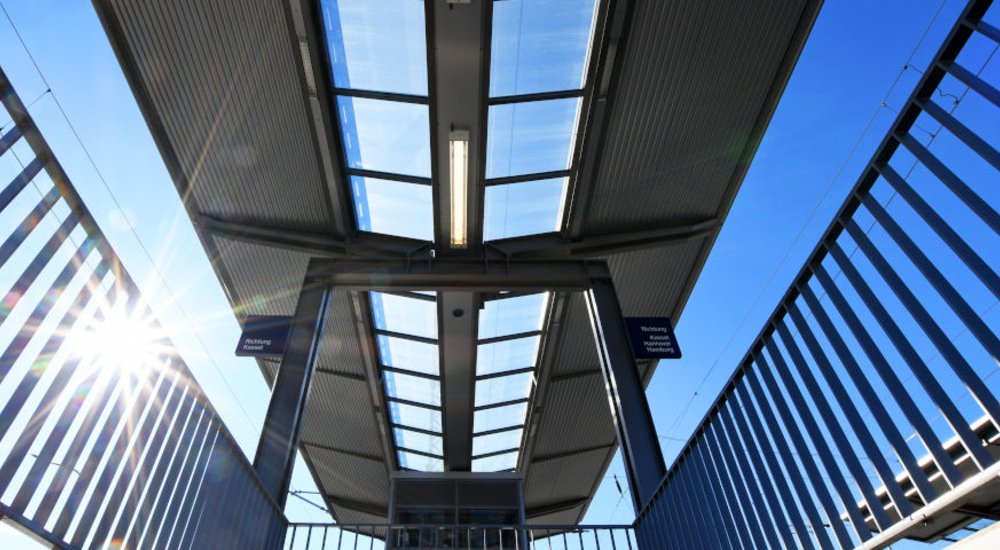

The major advantage of the Bodenheim roof compared to the Zwiesel roof is, amongst other things, quicker assembly on the platform. This is achieved by a high degree of prefabrication before installation takes place at the installation site. The Bodenheim platform roof can be used in many different geometries on central platforms as well as island platforms. The island variant of the platform roof is designed such that it can be used for all common platform widths from approx. 5 m to 13 m.

The roof cover is divided into two parts. The outer area towards the platform is covered with a trapezium sandwich profile whilst the middle area can either be covered using sandwich profiles or glass elements made of laminated glass. The integrated lighting takes both architectural and safety-relevant aspects into account. The loudspeakers on the PA system are also integrated in the roof.

In particular, important points regarding the improvement of platform roofs carried out by DB Station & Service AG such as accessibility of the roof via grates, location of lighting, etc., have been a feature of the Bodenheim since its introduction in 2002.

As you would expect, we will gladly assist you when planning your system room projects. In order to achieve cost-effective and functional solutions tailored around your project, we provide planning aids such as plan templates and ranges of Revit components in our digital planning catalogue.

At HERING, we see ourselves as pioneers in the field of sustainability. As early as 1996, we were the first construction company in Germany to obtain EMAS certification. Every three years, we publish an environmental statement documenting our goals and how we have achieved them. Actually, for the first time, we published a sustainability report with an integrated environmental statement in accordance with EMAS - a logical next step in view of our ecological and social responsibility. It documents how we deal internally and externally with the issues that are essential to our future viability.